Strategic Portfolio Management for Global Automotive Suppliers

Regain Control and Transparency in Complex Automotive Environments

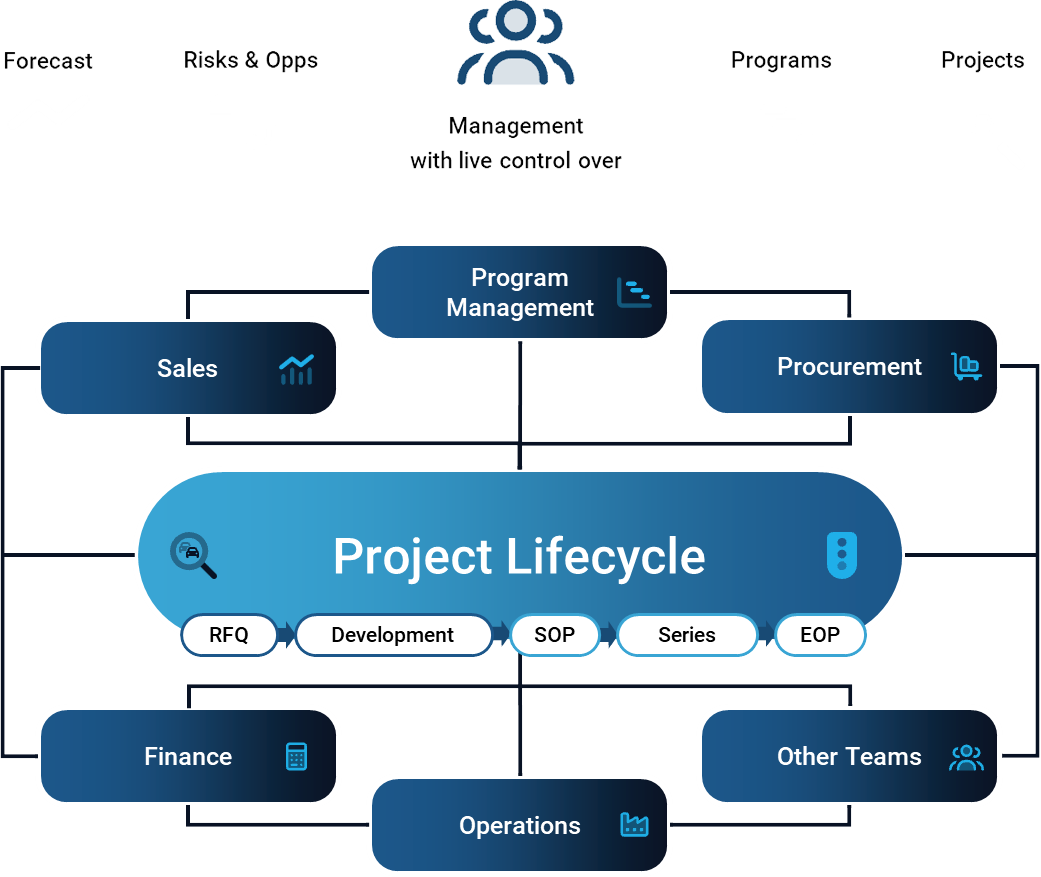

VISTAlution is an integrated steering platform that enables complete project transparency throughout the entire project lifecycle and supply chain and offers project execution in a seamless process from RFQ to profitable series production.

Integrates all relevant internal and external source data

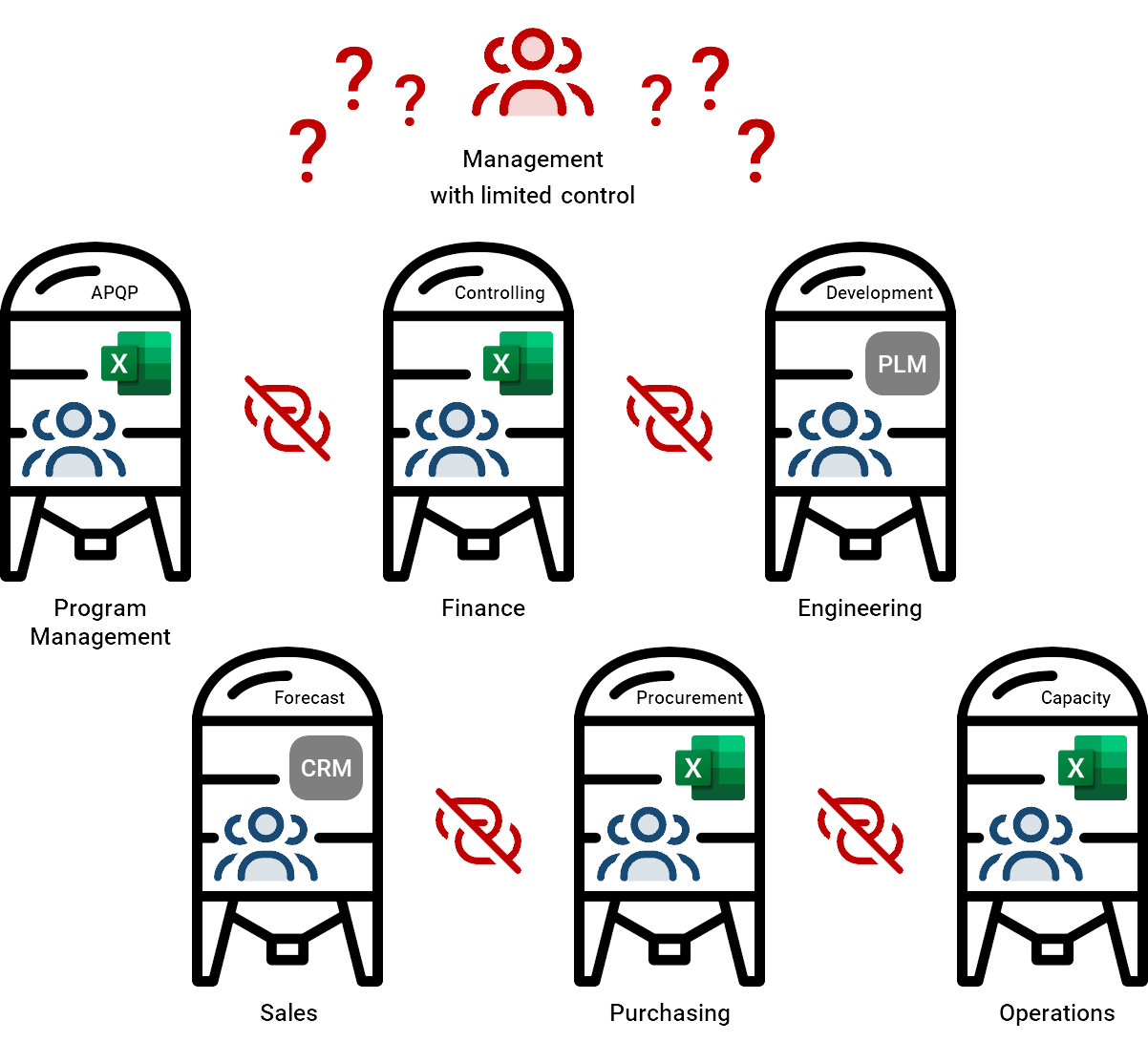

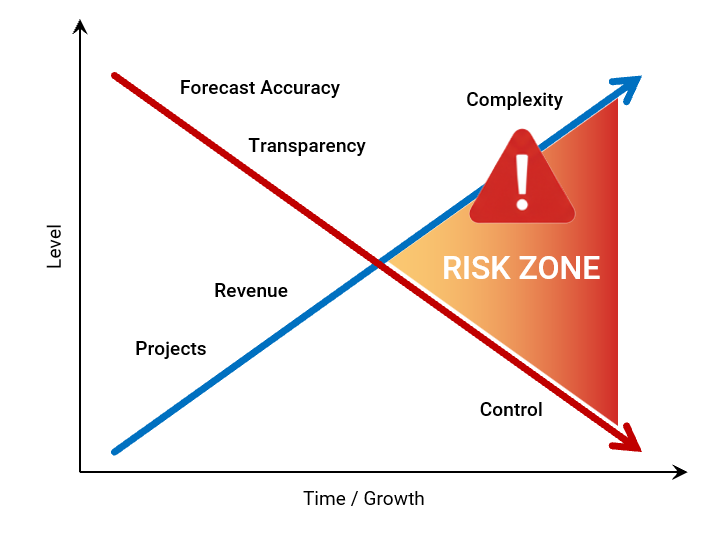

The Issue Behind Losing Steering Control

Increasing Complexity

Automotive suppliers are not struggling because of technology. They are losing control because complexity has outgrown their steering systems.

More projects. More part numbers. More OEM platforms. More SOP shifts. More supply chain volatility.

Planning, forecasting and execution still operate in separate silos.

When sales assumptions, program status and supply chain realities are not structurally linked, management decisions are based on fragmented perspectives instead of one consistent lifecycle view.

Growth without integrated transparency becomes a structural risk.

Over time, complexity starts driving the organization instead of management steering the business.

The Missing Link in Automotive Steering Models

Forecasts, project status and supply chain realities are not structurally linked

In many organizations:

- Sales forecasts are snapshots, not lifecycle-based commitments

- SOP shifts impact capacity and procurement too late

- Program risks do not flow back into financial steering

- Annual budgets lose relevance within months

The issue is not discipline. It is missing structural integration.

- Excel calculates, but it does not steer

- S&OP aligns aggregated volumes, but not lifecycle risk

- PM tools track milestones, but not financial impact

- PLM manages products, but not the commercial lifecycle from RFQ onward

Forecasting and project execution belong together.

Revenue depends on SOP timing. Margin depends on development stability. Investment decisions depend on realistic lifecycle assumptions.

When these elements are separated, management reacts to deviations instead of controlling outcomes.

Unconnected Silo Management

The Consequence - Growth Turns Into Risk

When lifecycle data is fragmented, executive steering becomes reactive

Strategic decisions are based on partial visibility instead of one consistent project view.

The effects are structural:

- Declining forecast reliability

- Late recognition of portfolio risks

- Margin erosion across projects

- Capital misallocation, overcapacity or delayed investment

- Growing operational firefighting

Growth continues. Control decreases.

Profitability is projected from assumptions instead of actively managed across the lifecycle.

The Solution

An integrated control model covering the entire project lifecycle

VISTAlution is not another isolated planning tool.

It is a steering platform built on one principle: the project is the central control unit.

One system. One data model. One consistent lifecycle logic from RFQ to EOP.

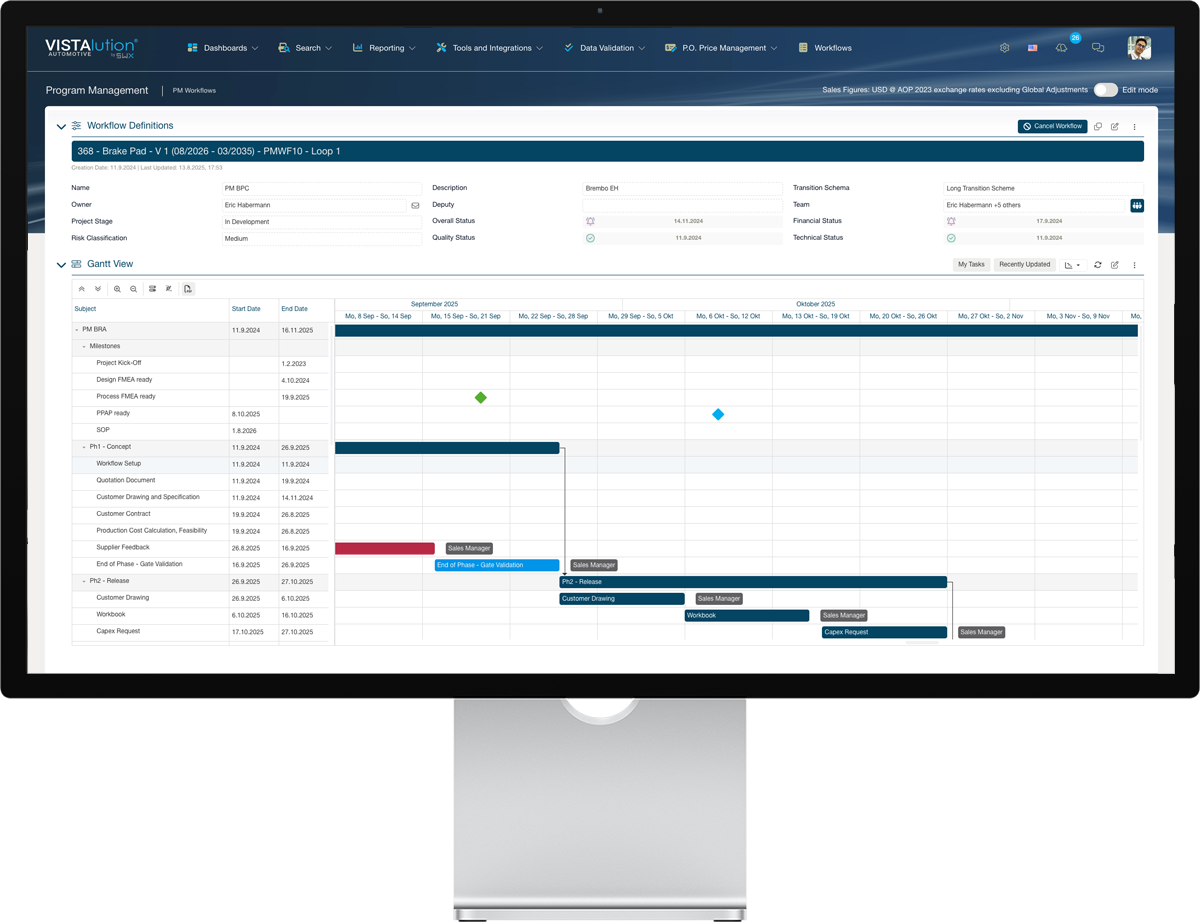

Sales forecasting, program management, procurement, capacity planning and strategic budgeting are structurally integrated instead of loosely connected.

Forecast and execution operate in one logic.

If a milestone shifts, revenue outlook, margin expectations, capacity load and procurement volumes adjust immediately. Executive impact becomes visible in real time.

VISTAlution integrates all relevant internal and external source data for planning. Sales data, RFQ pipelines, project milestones, BOM structures, capacity information, customer inputs and market assumptions are consolidated into one consistent data model.

This creates a single steering framework across the organization.

Planning becomes continuous instead of static. Forecast, budget and strategic scenarios remain aligned at any point in time.

Management does not reconcile numbers. It steers the lifecycle.

The Integrated Control Model

We Solve the Challenges in Forecasting and Project Execution

from separate processes to strategic success

Issue

With VISTAlution

- Bad data quality

Fragmented, incomprehensible project data

- Structured data

Chronological project-based data consolidation

- Lack of transparency

Decentralized data, no single source of truth

- Organization-wide transparency

Single source of truth for data-driven decisions

- Inconsistent planning processes

Repeating static one-time planning

- Continuous 360° forecasting process

Always up to date, taking customer orders and market data into account

- Missing traceable collaboration

Isolated activities, lack of cross-departmental alignment

- Cross-departmental documented collaboration

Traceable workflow-based collaboration

- Lack of control and analytics

Distributed data; inconsistent and outdated reports

- Integrated live control and BI analytics

Complete, live control over all projects

Click on a headline for details

90M

Light Vehicles

450+

Platforms

320+

SOPs

130+

OEMs

… require billions of products – properly managed, tracked and launched

We have the tools to successfully accomplish this

Our Planning and Management Solutions

for integrated strategic portfolio management

Who benefits from VISTAlution

- The Management

-

- Transparency and planning reliability

- Process reliability from RFQ to EOP

- Consistent database for strategy and decision-making

Resulting in increased profitability and competitiveness

- Sales Teams

-

- Complete project transparency

- Single source of truth for sales data

- Efficient planning process

Gaining sales management control, and souvereignty in negotiations with customers

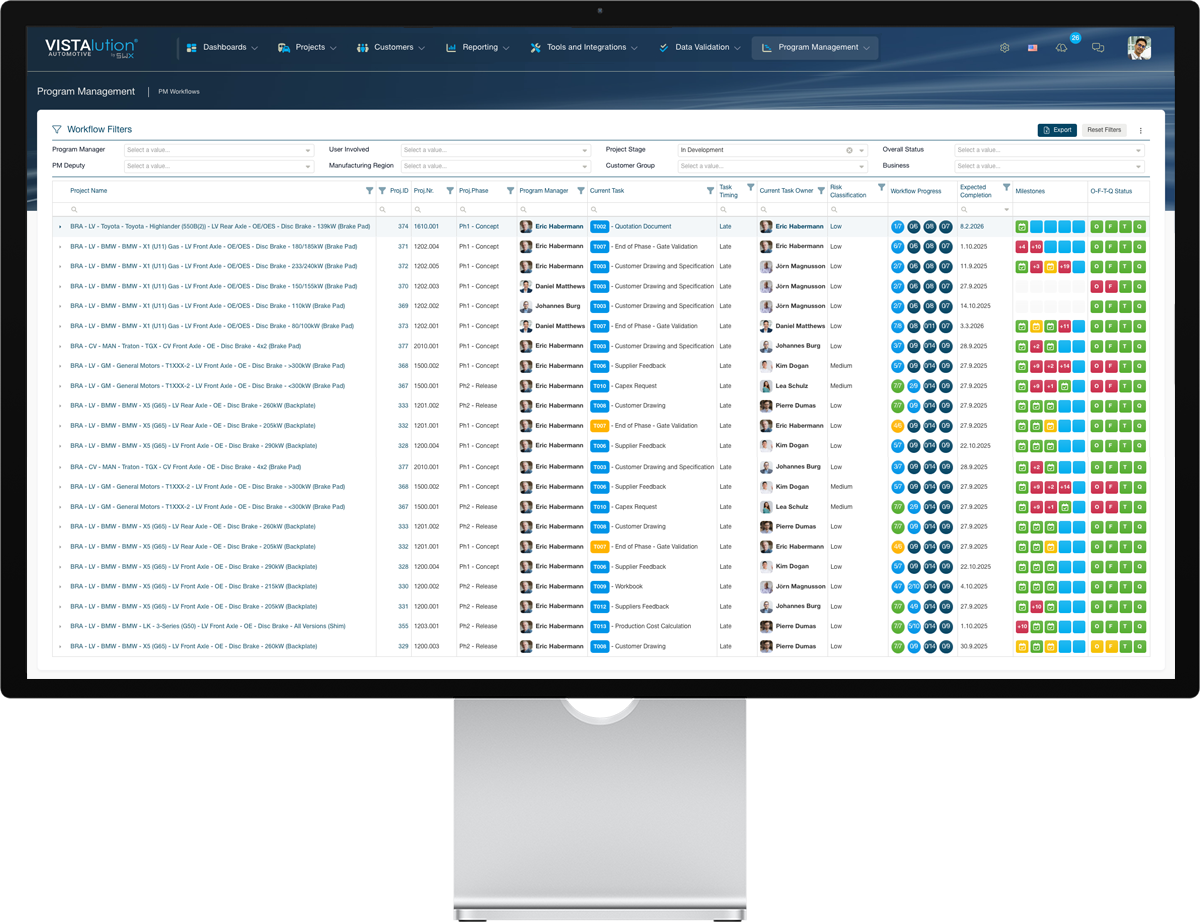

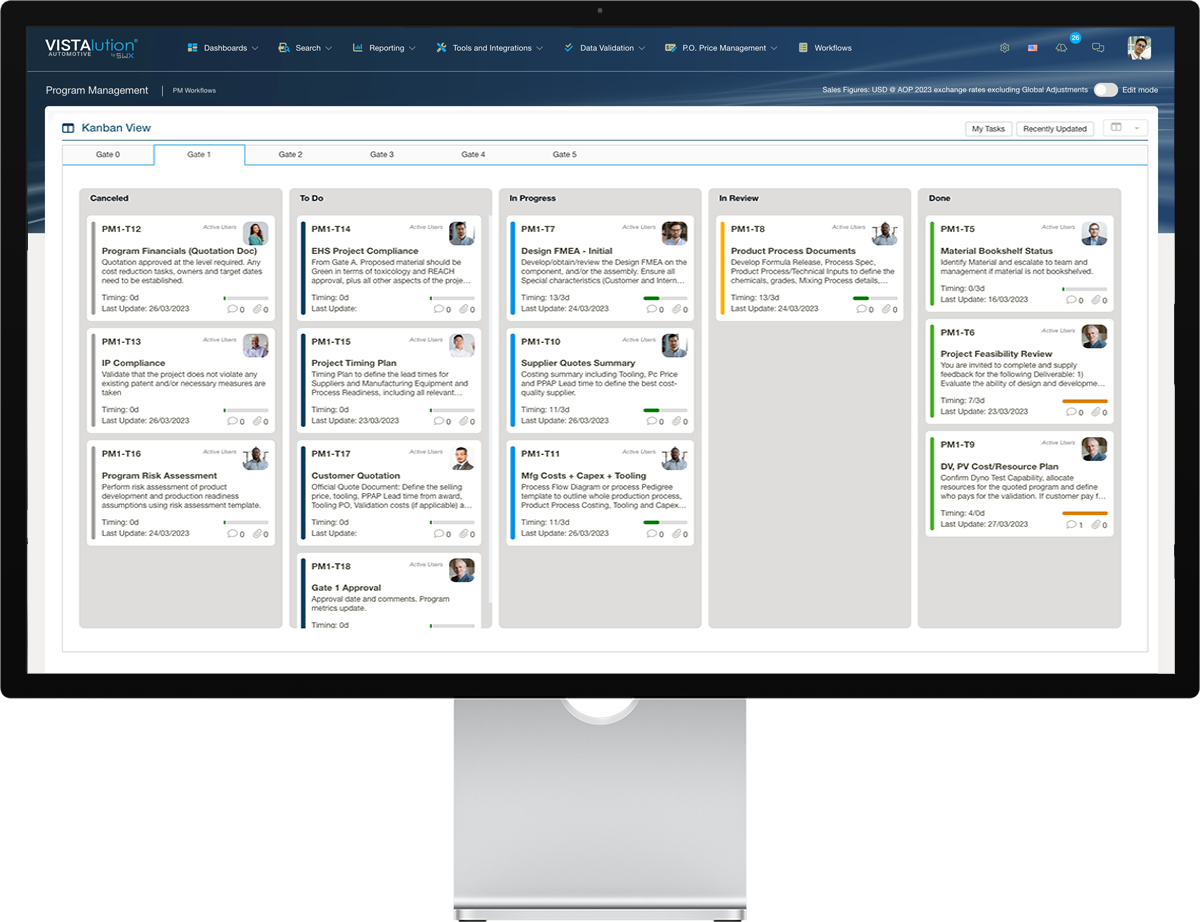

- Program Management

-

- Automated, predefined workflows

- Intuitive task and time management

- Flexible change management

Gaining live project control and traceability

- Other functions

-

- Single source of truth for project data

- Improved project-specific communication with colleagues

- High-quality data as a basis for own planning

Early involvement in the planning process and strategic alignment among departments

Minimal risk. Maximum implementation reliability.

Quickly productive through smart implementation

VISTAlution is professionally implemented. No dependence on internal IT resources.

Ready for productive use in just a few weeks.

Our promise of success

Our goal is to achieve measurable improvement in forecast and control quality.

If this added value is not confirmed after one year of intensive use*, we will stand by our performance promise.

Eligibility for funding

We will check whether your implementation is eligible for funding. Under certain conditions, up to 50% of the implementation costs can be subsidized.

Please contact us for more information.

Credentials

Companies from the world's top 20 automotive suppliers plan with our solution

What our customers say

Martin Kontny - Manager Global Sales Controlling & Planning

We were able to significantly increase our Planning accuracy. This enabled a more targeted procurement of resources and raw materials, more efficient use of R&D resources and led to higher customer satisfaction.

Özhan Nas - Director Quality

We have been able to realize large cost savings through better capacity utilization. The direct link between the sales plan and the capacity plan enables the AME team to allocate projects to machines more efficiently and thus to plan investments more precisely.

Ready for what comes next

A stable data and process foundation prepares your organization for future requirements – including new interfaces, increasing complexity and the meaningful use of AI-based analyses – without adding complexity today.

- ZNo IT involvement required

- ZFully operational within few weeks

- ZDesigned for daily use, not reporting only

- ZSupported onboarding and training